تجربیات

Experiences

Administrative skills & duties:

Deputy of Education, Dept. of Materials Engineering, Isfahan University of Technology (Since November/2013)

Director of Nanomaterials Group, Nanotechnology and Advanced Materials Institute, Isfahan University of Technology, Isfahan, Iran (2010-2012)

Deputy of Education, Dept. of Materials Engineering, Isfahan University of Technology (...

Experiences

Administrative skills & duties:

Deputy of Education, Dept. of Materials Engineering, Isfahan University of Technology (Since November/2013)

Director of Nanomaterials Group, Nanotechnology and Advanced Materials Institute, Isfahan University of Technology, Isfahan, Iran (2010-2012)

Deputy of Education, Dept. of Materials Engineering, Isfahan University of Technology (...

Development of Nanocrystalline TiNiCo Shape Memory Alloys via Thermomechanical Processing

(2011-2013) A university project supported by Iran National Science Foundation.

Development of Nanocrystalline TiNiCo Shape Memory Alloys via Thermomechanical Processing

(2011-2013) A university project supported by Iran National Science Foundation.

Synthesis of high intrinsic loss power aqueous ferrofluids of iron oxide nanoparticles for magnetic hyperthermia

2009-Present: A collaborative project with the School of Pharmacy, Isfahan Pharmaceutical Research Center, Isfahan University of Medical Sciences, Isfahan, Iran.

Synthesis of high intrinsic loss power aqueous ferrofluids of iron oxide nanoparticles for magnetic hyperthermia

2009-Present: A collaborative project with the School of Pharmacy, Isfahan Pharmaceutical Research Center, Isfahan University of Medical Sciences, Isfahan, Iran.

Development of nano/ultrafine grained carbon, bainitic and stainless steels by the Martensite thermomechanical processing

2007-Present: A collaborative project with the Iron and Steel Society of Iran

Development of nano/ultrafine grained carbon, bainitic and stainless steels by the Martensite thermomechanical processing

2007-Present: A collaborative project with the Iron and Steel Society of Iran

Development of directionally solidified (DS) and single crystal (SC) superalloy turbine blades

2010-Present: Isfahan University of Technology with the collaboration of Mapna-Parto Engineering Co.

Development of directionally solidified (DS) and single crystal (SC) superalloy turbine blades

2010-Present: Isfahan University of Technology with the collaboration of Mapna-Parto Engineering Co.

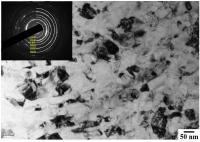

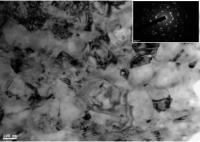

Application of Electromagnetic Levitational Gas Condensation Method for the Synthesis of Nanoparticles

2005-2007: Isfahan University of Technology with the collaboration of Defense Industries Organization of Iran

Application of Electromagnetic Levitational Gas Condensation Method for the Synthesis of Nanoparticles

2005-2007: Isfahan University of Technology with the collaboration of Defense Industries Organization of Iran

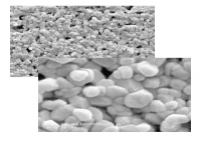

Synthesis of Alumina Micro-porous Substrates by Dip Coating Process and Titania Nano-porous Coating by Sol-Gel Process

2005-2007: Isfahan University of Technology with the collaboration of Institute of Standards and Industrial Research of Iran (Isfahan branch)

Synthesis of Alumina Micro-porous Substrates by Dip Coating Process and Titania Nano-porous Coating by Sol-Gel Process

2005-2007: Isfahan University of Technology with the collaboration of Institute of Standards and Industrial Research of Iran (Isfahan branch)

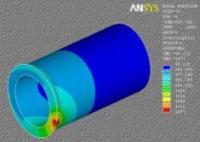

Thermal Simulation and Experimental Investigation of GTAW Circumferentially Butt-welded Incoloy 800 Pipes

2004-2007: Isfahan University of Technology with the collaboration of Oil Refinery Company of Isfahan

Thermal Simulation and Experimental Investigation of GTAW Circumferentially Butt-welded Incoloy 800 Pipes

2004-2007: Isfahan University of Technology with the collaboration of Oil Refinery Company of Isfahan

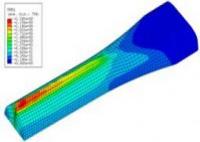

Thermo-mechanical Simulation of Shape Rolling of Structural Steel Rods at Kousar Rolling Mill

2006-2007: Isfahan University of Technology with the collaboration of National Industrial Group of Steel of Iran, Kousar Mill

Thermo-mechanical Simulation of Shape Rolling of Structural Steel Rods at Kousar Rolling Mill

2006-2007: Isfahan University of Technology with the collaboration of National Industrial Group of Steel of Iran, Kousar Mill

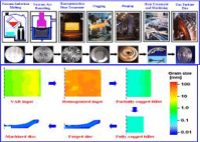

Integrated Process Modelling of the Manufacture of Gas Turbine Blade (IMMAD Programme)

2001-2004: Imperial College London with the collaboration of Special Metals Corporation, Special Metals Wiggin Ltd., Wyman-Gordon Ltd., Rolls-Royce plc, QinetiQ, Rolls-Royce UTP at University of Cambridge and the IRC in University of Birmingham.

Integrated Process Modelling of the Manufacture of Gas Turbine Blade (IMMAD Programme)

2001-2004: Imperial College London with the collaboration of Special Metals Corporation, Special Metals Wiggin Ltd., Wyman-Gordon Ltd., Rolls-Royce plc, QinetiQ, Rolls-Royce UTP at University of Cambridge and the IRC in University of Birmingham.